Regarding Mining Maintenance Support, diverse services and equipment are at your disposal. If you need help determining which options best meet your needs, our team of specialists is here to help you make an informed choice. Our extensive range of services and products includes:

PULLEY REMOVAL SYSTEMS

We have Safe and Efficient Tooling for installing and removing confined space pulleys and equipment. The SLED Pulley Removal System lets you remove pulleys outside the conveyor frame and walkways, facilitating side removal in areas with zero lift height constraints.

CONVEYOR BELT LIFTING SYSTEMS

We utilize our safe and efficient tooling, designed for removing and installing idlers and for various belt maintenance activities.

CONFINED SPACE PULLEY REMOVAL SYSTEMS

We use our 20-ton trolley Monorail Confined Space Pulley Removal System, designed to safely and efficiently remove and install pulleys and equipment in confined spaces.

CUSTOM CONVEYOR PROCESSING EQUIPMENT

We provide safe and efficient tooling for processing your materials, leveraging Discrete Element Modeling (DEM) for material flow analysis and Computational Fluid Dynamics (CFD) for fluid flow optimization.

MAGNET TRAMP METAL REMOVAL & CLEANING SYSTEM

Removing tramp metal from conveyors can be hazardous. Our Mine Works 360 tramp removal system is designed for quick and easy installation. It positions a permanent magnet over the nose of the conveyor. When needed, the powered winch safely and swiftly lowers the magnet to collect the tramp metal, depositing it into a dumpster. This efficient process allows for rapid return to operation, enhancing safety and minimizing downtime.

PUMP BARGES & FLOATING WALKWAYS

We provide safe and efficient service equipment for reclaim and PLS pond pumping. Our custom-designed floating walkways and pump barges are tailored to meet your requirements. Choose from powder-coated steel, hot-dipped galvanized steel, or 316 stainless steel for acid pond applications. Contact us for your barge and walkway solutions!

CUSTOM CONVEYOR FLOW TRANSITION DESIGN

We offer custom flow chute designs supported by Discrete Element Modeling (DEM) analysis to ensure your new chute system effectively meets all flow requirements.

COMPUTATIONAL FLUID DYNAMICS (CFD):

We utilize computer simulation techniques to analyze fluid flow and heat transfer within a part or system. This approach helps optimize design and identify potential issues early on.

Rigging and Lifting Tooling Design

We create custom lifting tools tailored to your specific installation requirements. We ensure precise design by scanning the part to be lifted and the surrounding environment. We provide training videos for pre-installation review that detail safe tool usage and its intended functionality.

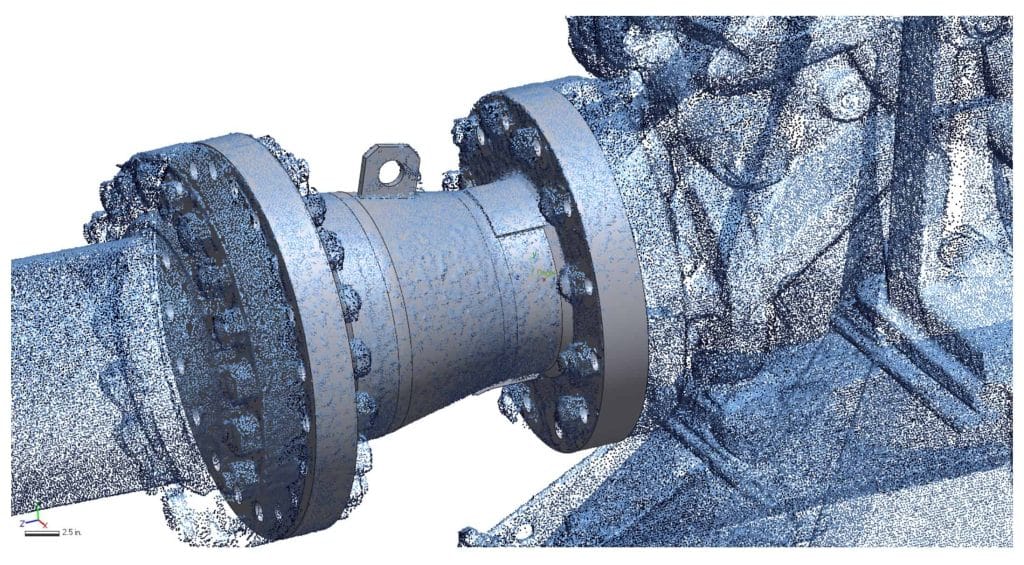

3D Part Scanning

At Mine Works 360, we leverage the Trimble X7 3D scanner to deliver top-tier 3D part scanning services. Our skilled team harnesses this advanced technology to accurately capture intricate details of your parts, minimizing rework and saving you valuable time and resources. We guarantee your components’ most precise and reliable 3D models through efficient workflows and intuitive software. Rely on Mine Works 360 for all your 3D part scanning needs confidently.

3D Point Cloud Processing

At Mine Works 360, we provide a comprehensive 3D point cloud processing service utilizing advanced software to convert raw point cloud data into various model formats. Our expert team manages the entire process, including point cloud registration, filtering, segmentation, and feature extraction, guaranteeing accurate and efficient results. This service applies across various industries, including as-builts, construction, architecture, and engineering. Trust us to handle your point cloud processing expert needs with confidence.

3D non-contact part dimensioning

Our service delivers accurate and efficient measurements of parts using cutting-edge 3D scanning technology. Utilizing non-contact methods, we capture data to precisely measure key dimensions such as length, width, height, and other critical features. We analyze your part scan data to deliver detailed dimensioning information. This service is ideal for various applications, including manufacturing and quality control. With our expertise, you’ll enhance accuracy and efficiency, enabling data-driven decisions that optimize your workflow and save time and money.

3D as-built verification

Using state-of-the-art 3D scanning technology, we capture precise measurements of your construction project to create an accurate digital model reflecting the as-built conditions. Our skilled engineers and technicians analyze the data to identify discrepancies between the designed and actual conditions. With our 3D as-built verification service, you’ll enjoy enhanced accuracy and efficiency, reduced risk of errors and rework, and improved project outcomes.

Reverse Engineering

We provide comprehensive reverse engineering solutions encompassing 3D scanning, CAD modeling, prototyping, and testing. Our services are ideal for anyone looking to replicate an existing product, enhance its design or functionality, or gain a deeper insight into its mechanics.