Mechanical Support Services offers a wide range of options. If you need help determining which service best fits your needs, our team of experts is here to help guide you. Here are some of the services we offer:

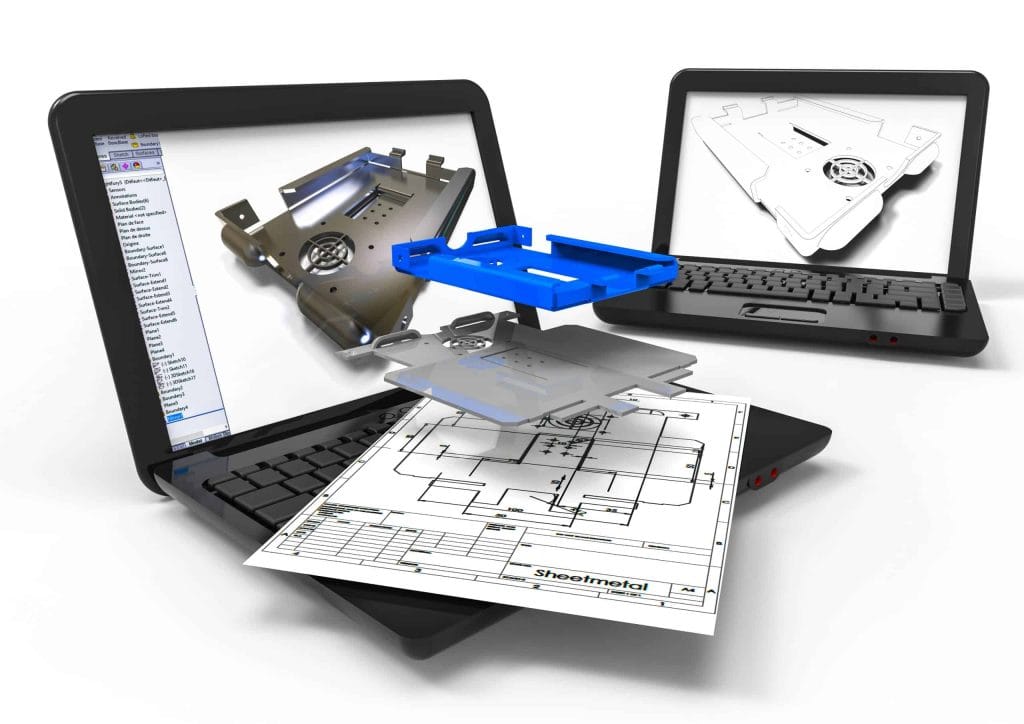

MECHANICAL DESIGN AND DRAFTING

We are a team of experienced mechanical designers and drafters with over 40 years of expertise designing complex tooling for commercial, industrial, mining, and aerospace applications. Our services encompass 2D and 3D design, drafting, prototyping, and manufacturing. We are dedicated to delivering our clients the highest quality services and products. Understanding the value of your time, we work swiftly and efficiently to complete your projects on schedule and within budget.

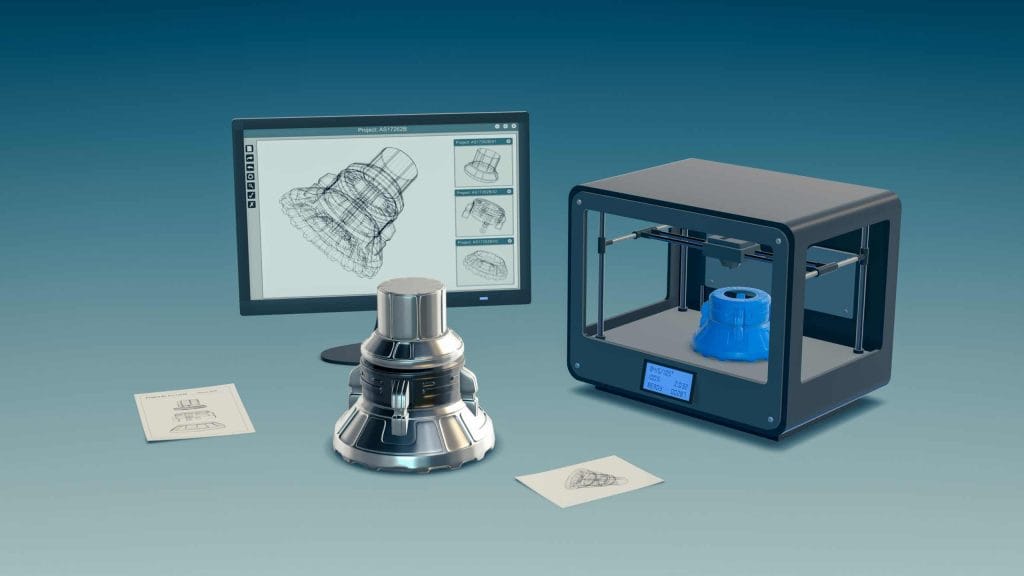

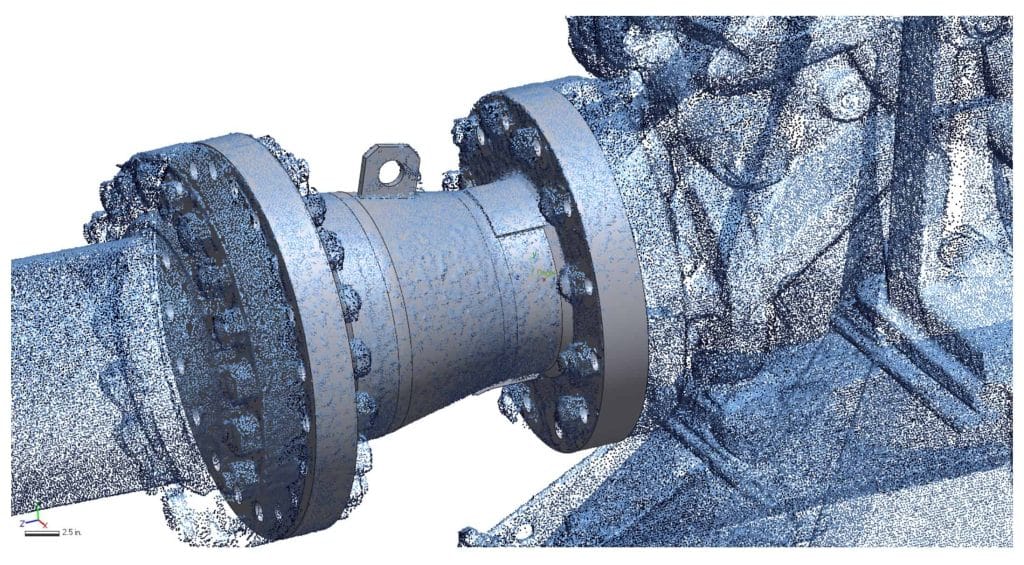

3D Part Scanning

At Mine Works 360, we use the Trimble X7 3D scanner to deliver exceptional 3D scanning services. Our skilled team employs advanced technology to accurately capture every detail of your parts, minimizing the need for rework and saving you time and money. With efficient workflows and user-friendly software, we ensure you receive reliable and precise 3D models of your components. Trust Mine Works 360 for all your 3D part scanning needs with confidence.

3D CAD MODELING

3D CAD modeling generates 3D computer models of systems or mechanical parts, allowing users to visualize and manipulate the design before manufacturing.

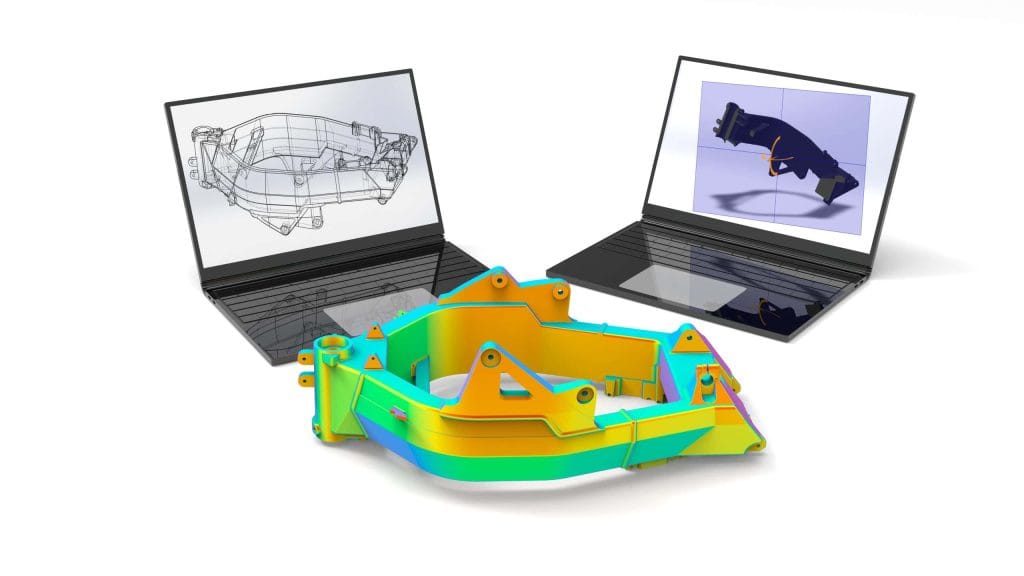

FINITE ELEMENT ANALYSIS (FEA)

FEA employs computer simulation techniques to analyze the mechanical behavior of a system or part under different loading conditions. This approach can be used to optimize the design and identify potential failures.

Computational Fluid Dynamics (CFD):

CFD utilizes computer simulation techniques to analyze fluid flow and heat transfer within a part or system. This method can help identify potential issues and optimize the design.

Product Development and Prototyping

This involves taking a new product from concept to production – encompassing design, prototyping, testing, and refining until it meets the desired specifications.

DISCRETE ELEMENT MODELING (DEM)

DEM is a computational technique used to simulate the behavior of granular materials. It represents particles as discrete elements and analyzes their motion and interactions within a system. Commonly employed to investigate the mechanics of bulk solids handling and processing equipment, DEM is also useful for studying the behavior of particulate materials in both natural and industrial processes.

Mechanical 3D Part Animation

Mechanical 3D Part Animation is a technique for creating animated visual representations of mechanical parts or systems. It utilizes 3D modeling software to develop a virtual model, which is then animated to illustrate its motion, operation, and functionality. This technique is often employed for design visualization, product demonstrations, and training. By leveraging Mechanical 3D Part Animation, engineers and designers can test and refine their designs, showcase product functionality, and communicate their ideas effectively.

PE stamped drawings and calculations packages

These refer to engineering documents that a licensed Professional Engineer (PE) has reviewed and approved. These documents generally include detailed engineering drawings and calculations for a construction or engineering project, stamped and signed by a PE to indicate compliance with all relevant codes and regulations. Regulatory bodies often mandate PE-stamped drawings and calculation packages to ensure the safety and integrity of construction or engineering projects.

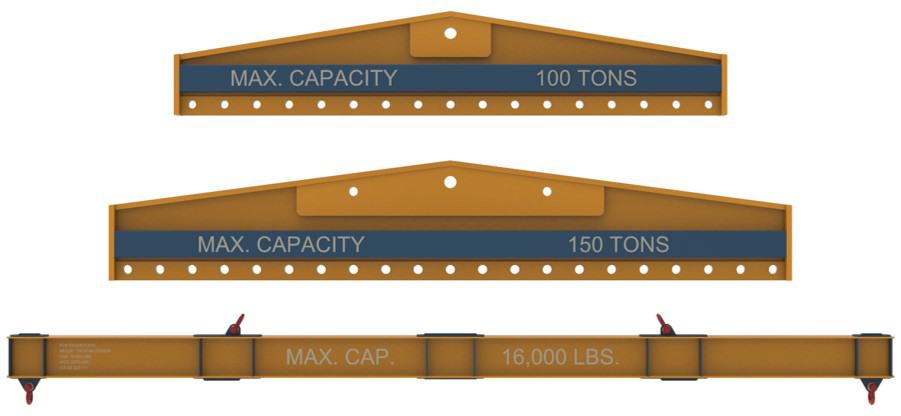

Rigging and Lifting Tooling Design

This refers to designing specialized equipment or tools for lifting and moving heavy loads. This design process involves analyzing the lifting operation’s requirements, such as the weight and dimensions of the load, and determining the most efficient and safe method for lifting and transporting it. Additionally, the rigging and lifting tooling design process considers environmental conditions, safety measures, and compliance with regulatory standards. The outcome is a specialized tool or set of tools optimized for the specific lifting operation, ensuring safety, efficiency, and effectiveness.

3D Part Scanning

At Mine Works 360, we utilize the Trimble X7 3D scanner to deliver top-tier 3D part scanning services. Our skilled team harnesses its advanced technology to capture every detail of your parts with exceptional accuracy and precision, minimizing rework and saving you time and money. With efficient workflows and intuitive software, we guarantee you receive your components’ most reliable and precise 3D models. You can trust Mine Works 360 to confidently manage your 3D part scanning needs.

3D Point Cloud Processing

At Mine Works 360, we provide a 3D point cloud processing service that utilizes advanced software to convert raw point cloud data into various model formats. Our expert team manages point cloud registration, filtering, segmentation, and feature extraction, ensuring accurate and efficient results. This service suits multiple applications, including as-builts, construction, architecture, and engineering. Trust us to handle your point cloud processing needs confidently.

3D non-contact part dimensioning

We deliver accurate and efficient measurements of parts using advanced 3D scanning technology. Our non-contact methods, including 3D scanning and imaging, capture data to precisely measure dimensions such as length, width, height, and other essential features. We analyze your part scan data and supply detailed dimensioning information. This service is suitable for various applications, including manufacturing and quality control. By choosing our service, you’ll enhance accuracy and efficiency while enabling data-driven decisions that optimize your workflow and save time and money.

3D as-built verification

Utilizing the latest 3D scanning technology, we capture precise measurements of your construction project to create an accurate digital model of the as-built conditions. Our experienced engineers and technicians analyze the data to identify discrepancies between the as-designed and as-built conditions. With our 3D as-built verification service, you’ll enjoy enhanced accuracy and efficiency, reduced risk of errors and rework, and improved project outcomes.

Reverse Engineering

We provide comprehensive reverse engineering solutions that encompass 3D scanning, CAD modeling, prototyping, and testing. Our services are ideal for anyone looking to replicate an existing product, enhance its design or functionality, or gain a deeper insight into its operation.